Power electronic converters are vital components in modern electrical and electronic systems, designed to transform electrical energy from one form to another in order to meet specific load or system requirements. These circuits regulate key parameters such as voltage level, current magnitude, and frequency, enabling seamless integration between power sources and end-use devices.

At the core of these converters are high-speed semiconductor switching devices – such as MOSFETs, IGBTs, and diodes that manage the controlled transfer of electrical energy with high efficiency. By leveraging advanced control strategies, converters ensure precise and stable power delivery under dynamic operating conditions.

Classification of Power Electronic Converters

Power electronic converters are essential in modern electrical systems, enabling the efficient transformation of electrical energy between different forms to meet the functional requirements of various applications. These converters are broadly categorised based on the type of input and output electrical signals like AC or DC (Refer Chart 1).

AC to DC Converters (Rectifiers)

AC to DC converters, commonly known as rectifiers, are fundamental components in electrical and electronic systems. Their primary function is to convert Alternating Current (AC) typically sourced from the power grid into Direct Current (DC), which is required for the operation of most modern electronic devices and systems.

This conversion process is essential in a wide range of applications, including consumer electronics, industrial controls, renewable energy systems, battery charging, and DC motor drives. Depending on the design requirements, rectifiers can deliver unregulated or regulated DC output, often followed by filtering and voltage control stages.

Working Principle of Rectifiers

The core operation of a rectifier is based on controlling the direction of current flow using semiconductor devices such as diodes and thyristors. Since AC alternates in polarity, rectifiers selectively allow current to pass in only one direction, effectively converting the bidirectional waveform into a unidirectional flow.

To produce a smoother and more usable DC output, rectifier circuits often incorporate filtering components (capacitors, inductors) and in many cases, a voltage regulation stage using linear or switching regulators.

Types of Rectifiers

Half-Wave Rectifier

- Uses a single diode to pass only one half-cycle of the AC signal.

- Simple design but provides a pulsating and inefficient DC output.

- Mainly used in low-power applications.

Full-Wave Rectifier (Center-Tapped Transformer Based)

- Employs two diodes and a center-tapped transformer to utilise both halves of the AC input.

- Results in better efficiency and smoother output than half-wave rectifiers.

Bridge Rectifier

- Comprises four diodes arranged in a bridge configuration.

- Eliminates the need for a centre-tapped transformer.

- Provides full-wave rectification with improved efficiency and compact design.

- Common in most modern power supply units.

Controlled Rectifiers (Using SCRs or Thyristors)

- Allow regulation of output voltage by controlling the firing angle of the SCRs.

- Widely used in industrial power supplies, variable-speed drives, and high-voltage DC (HVDC) systems.

Power Quality Considerations

Basic rectifiers can introduce harmonics and power factor issues into the AC supply. To address these, advanced systems employ:

- Filter circuits (LC or RC types)

- Boost converters

- Power Factor Correction (PFC) stages

These ensure a more stable and sinusoidal input current, improve energy efficiency, and meet modern electromagnetic compatibility (EMC) standards.

Applications of AC to DC Converters

- Consumer Electronics: Mobile chargers, televisions, and computer power supplies.

- Industrial Automation: PLCs, sensors, and servo drives requiring stable DC voltage.

- Battery Charging Systems: For EVs, UPS systems, and renewable energy storage.

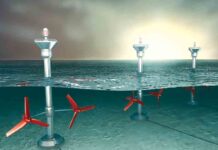

- Renewable Energy Integration: Converting AC from wind generators into DC for storage or further conversion.

- DC Motor Drives: Where variable DC voltage is needed for speed and torque control.

DC to DC Converters (Choppers)

DC to DC converters, commonly known as choppers, are static power electronic devices used to convert a constant Direct Current (DC) input into a regulated DC output at a different voltage level. These converters are essential in modern power systems where voltage flexibility, efficiency, and miniaturisation are crucial particularly in applications such as electric vehicles, renewable energy systems, portable electronics, and embedded systems.

Working Principle

The basic operation of a chopper is to switch the DC input on and off rapidly using semiconductor devices such as MOSFETs, IGBTs, or power BJTs.

The duty cycle (the ratio of ON time to total switching period) is modulated to control the average output voltage. This high-frequency switching, often in the range of tens to hundreds of kilohertz, allows precise voltage regulation with high efficiency and compact size.

A typical chopper circuit includes:

- A switching device

- A diode (for freewheeling or reverse current protection)

- Inductors and capacitors (to filter and smooth the output)

Types of DC-DC Converters

Buck Converter (Step-Down):

- Reduces the input voltage to a lower level.

- Widely used in battery-powered systems and voltage regulators for CPUs, GPUs, and microcontrollers.

Boost Converter (Step-Up):

- Increases the input voltage to a higher level.

- Common in applications like photovoltaic systems, LED drivers, and power supplies for communication devices.

Buck-Boost Converter:

- Capable of both stepping up and stepping down the voltage.

- Suitable where input voltage may vary above or below the required output voltage.

Cuk and SEPIC Converters:

- Provide non-inverting and flexible voltage conversion.

- Known for better input/output current characteristics and reduced ripple.

Control Techniques:

DC-DC converters use various control methods to regulate output voltage:

- Pulse Width Modulation (PWM): Adjusts the duty cycle to control output.

- Current Mode Control: Enhances response and protects against overcurrent.

- Voltage Mode Control: Maintains a constant output voltage using feedback loops.

Modern converters often integrate digital control algorithms, such as PID controllers or adaptive control, implemented via microcontrollers or DSPs.

Applications

DC-DC converters are extensively used in:

- Electric Vehicles (EVs): Managing voltage levels between batteries, motors, and control units.

- Renewable Energy Systems: Matching solar panel voltage to battery or grid interfaces.

- Telecommunication Equipment: Powering routers, modems, and data centers with regulated DC outputs.

- Consumer Electronics: Ensuring efficient power supply in laptops, smartphones, tablets, and cameras.

- Industrial Automation: Driving control circuits, PLCs, and sensors with precise DC power.

Advantages

- High efficiency (typically 85–95%)

- Fast transient response

- Compact size due to high-frequency operation

- Precise voltage control and regulation

- Isolation (in isolated topologies, such as flyback or forward converters)

DC to AC Converters (Inverters)

An inverter is a power electronic device that converts a constant Direct Current (DC) input into a controlled Alternating Current (AC) output. This process is fundamental in a variety of applications, especially where the primary energy source provides DC such as batteries, fuel cells, or photovoltaic (solar) panels but the load or grid demands AC.

Unlike a fixed DC input, the output of an inverter is typically variable in both voltage and frequency, allowing for flexible and efficient operation across different systems. The inverter’s core functionality is achieved by switching semiconductor devices on and off in a controlled manner to generate a waveform that closely approximates a sinusoidal AC signal.

Working Principle and Switching Devices

Inverters use high-speed semiconductor switches to construct an AC waveform from a DC source. The process may involve different control strategies, such as square wave, modified sine wave, or Pulse-Width Modulation (PWM) with PWM being the most common due to its ability to generate a clean and efficient output with reduced harmonic distortion.

Key switching devices used in inverters include:

- MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors)

- IGBTs (Insulated-Gate Bipolar Transistors)

- GTOs (Gate Turn-Off Thyristors)

- Power BJTs

- SCRs or Thyristors

The selection of devices depends on the power level and switching frequency. For instance, thyristors are preferred in high-power applications due to their ability to handle large currents, while MOSFETs and IGBTs are widely used in medium and low-power applications due to their fast switching and efficiency.

In thyristor-based inverters, commutation techniques (line commutation, load commutation, or forced commutation) are required to turn off the devices, since they cannot self -turn-off by gate control once they are conducting.

Types of Inverters

- Voltage Source Inverters (VSI): These use a fixed DC voltage input and generate an AC voltage output.

- Current Source Inverters (CSI): These operate with a constant DC current input and produce an AC current output.

- Single-phase and Three-phase Inverters: Depending on the output requirement and load type.

Applications of Inverters

Inverters play a central role in various domains, including:

- Electric Drives: For controlling AC induction or synchronous motors in industrial automation and electric vehicles.

- Uninterruptible Power Supplies (UPS): Providing backup AC power during grid failures.

- Solar PV Systems: Converting DC from solar panels into AC for home or grid use.

- HVDC Transmission Systems: Converting high-voltage DC to AC for grid reintegration.

- Aerospace and Military Power Supplies: Where lightweight and efficient AC sources are needed from DC systems.

- Portable Devices: Such as flash circuits in photography and small-scale induction heating setups.

AC to AC Converters

AC to AC converters are specialised power electronic devices that directly modify an Alternating Current (AC) input into an AC output with a different voltage, frequency, or phase configuration without first converting it into DC. These converters play a vital role in modern electrical and industrial systems, especially where variable AC power is required for control, compatibility, or synchronization purposes.

The two major categories of AC to AC converters are::

Cycloconverters

Cycloconverters directly convert input AC at one frequency (typically the grid frequency, 50/60 Hz) to a lower-frequency AC output without using an intermediate DC link. This is achieved through controlled switching of semiconductor devices such as thyristors in either a step-down (f < f_input) or variable frequency mode.

- Operation: Cycloconverters synthesize the output waveform by sampling segments of the input waveform and reconstructing them at the desired frequency.

- Applications: Ideal for low-speed, high-power AC motor drives, especially in industries like cement mills, rolling mills, and ship propulsion systems.

- Advantages: Direct frequency conversion, good torque control at low speeds, and suitability for very large power ratings.

- Limitations: High harmonic content and limited output frequency (typically <1/3 of input frequency).

Matrix Converters

Matrix converters are advanced AC-AC converters that consist of an array of bidirectional switches arranged in a matrix format. They allow for direct conversion of input AC to output AC with controllable voltage and frequency, offering a compact and transformer-less solution.

- Operation: These converters dynamically control the switching pattern using advanced modulation techniques such as Space Vector Modulation (SVM) to generate a sinusoidal output.

- Applications: Used in aerospace, motor drives, wind turbine interfaces, and systems requiring compact and efficient AC power conversion.

- Advantages: High power density, bidirectional power flow, and regenerative capability.

- Limitations: Complex control circuitry and demanding protection requirements for bidirectional switches.

Conclusion

Power electronic converters are crucial in shaping and managing electrical energy to meet the operational needs of diverse systems and devices. Whether transforming AC to DC, DC to DC, DC to AC, or AC to AC, each converter type plays a specialised role in improving efficiency, stability, and control of power flow.

By leveraging high-speed semiconductor devices and advanced control strategies, these converters enable compact, reliable, and efficient energy solutions across industries ranging from consumer electronics and industrial automation to electric vehicles and renewable energy systems.

They also address challenges like harmonics, voltage fluctuations, and power quality through integrated filtering and correction techniques.

As demand for smarter and more adaptable energy systems grows, the importance of power electronic converters continues to expand, supporting innovation in modern power infrastructure and contributing to the global shift toward cleaner, more sustainable energy technologies.

Dr. Bidrohi Bhattacharjee holds a Ph.D. in Electrical Engineering from the Indian Institute of Technology (ISM), Dhanbad, India. He earned his B.E. in Electrical Engineering and M.Tech. in Illumination Technology and Design from Jadavpur University, Kolkata, West Bengal, India. Currently he is working as HoD and Assistant Professor at the Electrical Engineering Department in Budge Budge Institute of Technology, Kolkata, India. His research interests span power electronics, electric drives, renewable energy, sustainable development, electric vehicles, and battery charging technologies. He also holds several patents in the areas of power electronics, renewable energy, and electric vehicles.