- Introduction

The journey to modern electrical system reliability starts with careful evaluation of existing infrastructure and extends through smart retrofitting, precise integration, and thorough testing. By upgrading legacy systems with advanced technologies like IEC 61850 relays, PMS controllers, and synchronized communication networks, industries can achieve high reliability, fast fault response, intelligent load management, and efficient, uninterrupted power delivery.

A. Critical Pillars of Efficient Electrical System Retrofitting

Achieving long-term operational excellence requires a strategic approach blending market insight, technical precision, and organizational readiness. With 80% effort on meticulous planning and 20% on execution, this ensures all aspects–from understanding market trends and corporate perceptions to selecting advanced, innovative solutions–are thoroughly addressed before implementation.

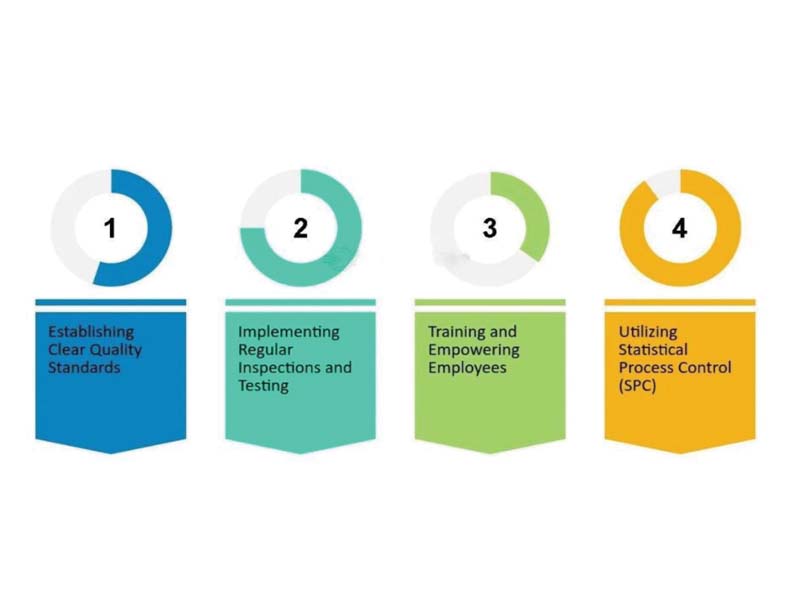

As illustrated in Fig. 1, selecting the right solutions balances technical features with practical value, focusing on durability, reliability, and cost efficiency. Success in live plant environments relies on careful planning, seamless integration, and strict safety. Systems undergo thorough testing and validation to ensure flawless operation. True efficiency combines robust engineering with skilled, engaged personnel. Quality is continuous, supported by inspections, clear standards, data-driven controls like SPC, and a culture of ongoing improvement.

B. Harnessing Digitalization and Automation for Smarter Power Systems

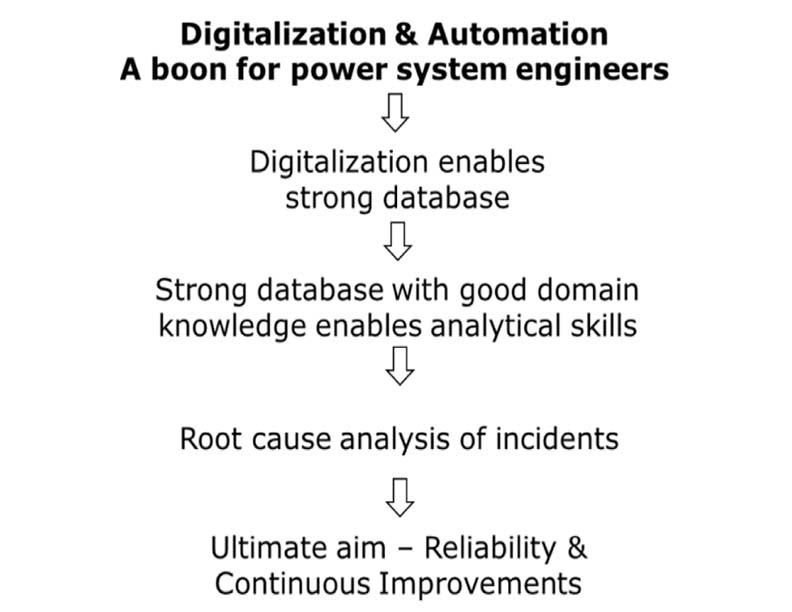

Through modern technologies are transforming power system supervision through careful planning and advanced engineering. High-speed data acquisition captures real-time load fluctuations and historical fault patterns, enabling engineers to quickly analyze and identify causes of events like transformer trips, generator overloads, or equipment failures.

As shown in Figure-2, digitalization and automation enable power engineers to access and analyze real-time and historical data. Advanced analytics help quickly identify disturbances, implement corrective actions, minimize downtime, and improve the efficiency, safety, and reliability of power plants and grids.

- Intelligent Protection: The Role of Relays / IEDs, and IEC 61850

Modern electrical networks rely on advanced relays and Intelligent Electronic Devices (IEDs) to continuously monitor voltage, current, and frequency, quickly isolating faults or overloads to protect equipment and maintain stability. Beyond protection, these devices offer communication, event recording, and remote control.

The real breakthrough comes with IEC 61850, the global standard for digital power system automation.

IEC 61850 – Smarter, Faster Power Systems:

- GOOSE Messaging: Instant protective action in milliseconds

- Sampled Values (SV): Real-time precise measurements

- MMS Protocol: Multi-vendor device communication & control

- Time Synchronization: Perfect coordination across devices

- Centralized Control & Analytics: Smart monitoring and faster decisions

- Fast Fault Clearance: Minimized downtime, maximum reliability

- From Strategy to Action: Real-Time Deployment of Protection Management Systems (PMS)

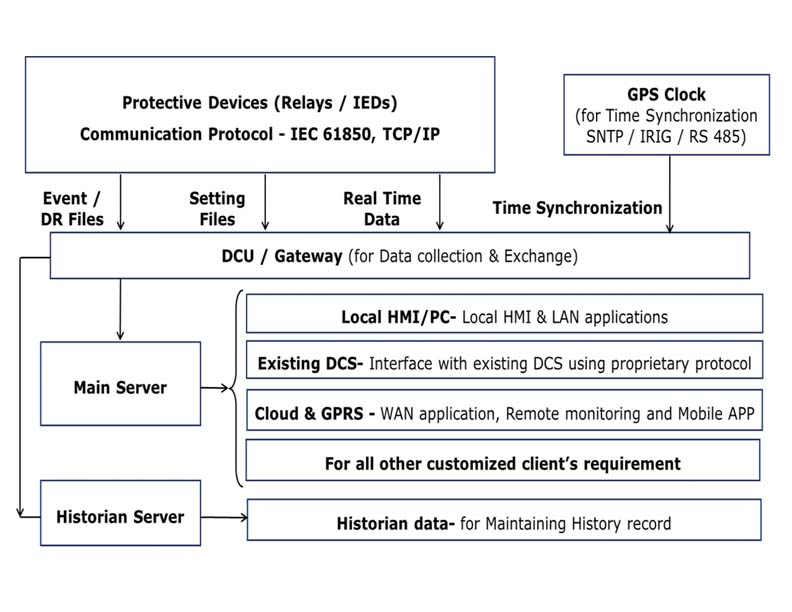

Building on intelligent electronic devices and the IEC 61850 standard, Protection Management Systems (PMS) introduce a new level of reliability, intelligence, and operational efficiency to modern power networks. As depicted in Fig. 3, PMS offers a unified platform for monitoring, control, and protection, enabling seamless remote relay setup, configuration transfers, live disturbance tracking, and highly precise time synchronization across all connected devices. The system effortlessly integrates both modern and legacy equipment while ensuring smooth interoperability with local HMIs, plant SCADA networks, enterprise cloud infrastructures, and wireless communication channels.

All collected information-including event histories, disturbance waveforms, and fault records-is securely archived to support advanced diagnostics, root-cause analysis, and predictive performance optimization. By combining protection, communication, and analytics into one intelligent, adaptive ecosystem, PMS enhances system availability, accelerates fault recovery, improves decision-making, and ensures reliable, efficient, and future-ready operation for power systems across industrial and utility environments.

- Case Study: Real time implementation of PMS in Chemical plant

Problem Statement

A leading chemical manufacturing facility operates with two Steam Turbine Generators (STGs) running in parallel, connected to a 66 kV grid. The plant faced recurring challenges during power interruptions, as the existing setup struggled to accurately track and differentiate disturbances due to limited communication and inconsistent time synchronization.

Problem Identification

The primary issue arose from an unreliable automatic load-shedding scheme, relying on fragmented control logic and lacking coordinated event management. Communication gaps between devices, coupled with the absence of unified time alignment, further hindered post-event analysis. Consequently, plant operations experienced:

- Difficulty in determining the root cause of grid and plant-side disturbances.

- Delayed response to sudden grid faults and generator trips.

- Increased downtime due to manual intervention.

Proposed Solution with Implementation:

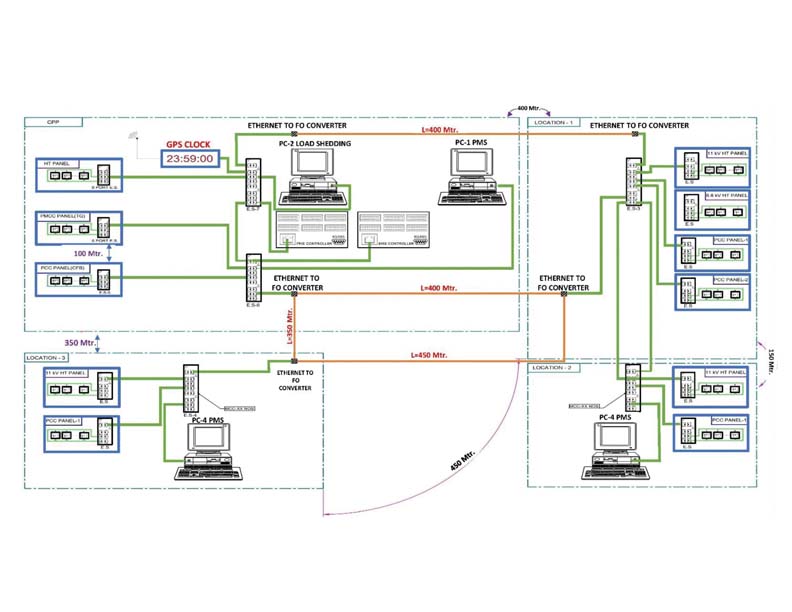

These challenges highlighted the need for a centralized system to integrate control, monitoring, and event management functions, ensuring synchronized data collection, accurate fault identification, and streamlined operational oversight. To overcome the challenges posed by the existing unreliable automatic load-shedding scheme, a comprehensive, centralized system with full time synchronization has been implemented.

As illustrated in Fig. 4, the system integrates Schneider and ABB IEC 61850-compatible relays, PMS controllers, and a GPS time synchronization network to establish a fully automated, intelligent, and fault-resilient load-shedding framework. By unifying protection, control, and monitoring on a single IEC 61850-enabled platform, it ensures rapid fault response, precise event sequencing, and significantly enhances overall plant reliability and operational efficiency.

Key Highlights:

IEC 61850 Integration:

- Schneider and ABB relays are seamlessly integrated with PMS controllers through an IEC 61850 communication backbone.

GPS Time Synchronization:

- A GPS server with clock display provides accurate time synchronization across all devices for reliable event recording and post-disturbance analysis.

Intelligent Load Shedding (ILS):

- Prioritizes critical loads

- Enforces maximum-demand limits

- Provides under-frequency backup to maintain plant stability

Unified Protection & Control:

- Common IEC 61850 network supports both protection management and operational

control, ensuring - coordinated relay settings and fast response to grid faults or generator trips.

Automated & Resilient Framework:

- Enables rapid disturbance identification

- Reduces manual intervention and downtime

- Improves overall reliability and operational efficiency

- Conclusion

The transition from a fragmented, conventional load management approach to a centralized, IEC 61850-enabled PMS represents a paradigm shift in plant reliability. By combining PMS controllers, ILS logic, GPS-based time synchronization, and seamless relay integration, the solution not only addresses historical pain points but also future-proofs operations. Real-time fault identification, automated corrective actions, and unified event management minimize downtime, reduce reliance on manual intervention, and ensure uninterrupted production. Ultimately, this modernization establishes a resilient, intelligent, and fully coordinated power infrastructure that enhances operational stability while laying the groundwork for scalable digital transformation.

Rohan K. Mehta received the B. Tech degree in Electrical Engineering from Nirma University, Ahmedabad, India in 2008. He is Director-Engineering at Elcon Engineers Pvt. Ltd., with over 17 years of experience in power system simulation and solutions alongside power automation solution. This article includes valuable contribution from Er. Shubham SR. Singh from Elcon Engineers Private Limited.

For more information visit website: www.elconengineers.com

Email: rmehta@elconengineers.com, pas@elconengineers.com