- Introduction

The Intelligent Load Management System (ILMS) is a modern approach to industrial power management, designed to keep operations running without disruption. By intelligently generation control, balancing demand, and shedding non-essential loads when required, ILMS ensures continuous supply to critical facilities and stable plant operations.

What distinguishes the ILMS is its foundation on the IEC 61850 communication standard, enabling seamless integration with Intelligent Electronic Devices (IEDs). This architecture ensures true interoperability, real-time monitoring, and effortless scalability–positioning ILMS not merely as a power management solution, but as a forward-compatible energy platform for industrial applications.

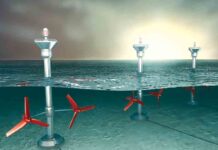

Figure 1 illustrates the ILMS, where turbine generators, the grid, and the bus coupler operate in coordination–synchronizing power, optimizing load sharing, and ensuring system reliability through fast and intelligent load shedding.

- ILMS with IEC 61850: Adaptive Control in Next-Gen Power Systems

The evolving power landscape, characterized by increasing demand and complex networks, demands advanced, adaptive control strategies. Traditional systems relying on manual interventions or proprietary protocols lack the responsiveness and interoperability required by modern substations and industrial facilities. Integrated with IEC 61850, ILMS delivers the intelligence and standardization essential for reliable, scalable energy management.

A) IEC 61850, as the standard for ILMS communication

IEC 61850 is not limited to substations-it has become a universal standard for industrial power system automation. In ILMS, it acts as the digital backbone that enables fast, secure, and standardized communication across different IEDs within plants, factories, and critical industrial facilities. Its role ensures coordinated operation of distributed energy sources, process equipment, and protection systems.

B) Driving Functions of IEC 61850

In ILMS, IEC 61850 serves as the digital backbone that revolutionizes industrial power automation. It provides standardized logical nodes for consistent data representation, GOOSE messaging for high-speed communication during critical events, and MMS for reliable system monitoring and control. By enabling seamless interoperability across Intelligent Electronic Devices (IEDs) and simplifying infrastructure through reduced wiring, IEC 61850 streamlines system design and deployment. With these capabilities integrated into ILMS, the system delivers high-speed automation, vendor-independent interoperability, enhanced reliability through rapid fault isolation and recovery, and optimized load distribution–ensuring continuous power supply to critical equipment.

Figure 2 depicts the IEC 61850 communication framework within ILMS, illustrating the integration of SCADA systems, HMIs, IEDs, and process-level devices across station and process buses, all functioning within a secure communication boundary.

- Deploying ILMS with IEC 61850: Field-Tested Case Studies Across Industries

The strength of ILMS is best demonstrated through real industrial case studies. In the paper industry, it delivered high-speed IEC 61850-based load shedding, while in the tire industry, intelligent generation control and smart load-sharing improved reliability. These examples highlight how ILMS with IEC 61850 ensures resilient, efficient, and disruption-free power management.

Case-1

A paper manufacturing plant operating with four STGs connected to a 66 kV grid faced frequent power interruptions and unexpected blackouts. The root cause was an unreliable automatic load-shedding system, which lacked speed and consistency. The plant required a more reliable, relay-based communication load-shedding solution that could eliminate additional control wiring while ensuring fast, fully automated response during power disturbances.

Proposed Solution:

As shown in Figure 3, a fully IEC 61850-native Intelligent Load Shedding (ILS) scheme was implemented end-to-end, eliminating the need for additional control wiring. Breaker statuses and analog measurements–including kW, kVAr, voltage, current, power factor, and frequency–are acquired from both existing relays and newly installed IEC 61850-enabled controllers. The ILS logic, hosted within these controllers, prioritizes loads, enforces maximum demand limits, and provides under-frequency load shedding as a backup. Shedding and restoration commands are transmitted to designated feeder breakers via peer-to-peer IEC 61850 communication, enabling fast, deterministic responses and enhancing system reliability with minimal downtime. The system has proven its reliability and effectiveness through sustained field operation in demanding conditions.

Case-2

A leading tire manufacturing plant, which operated with three steam turbine generators (STGs) and a 66 kV grid connection, faced critical operational challenges. These included difficulties in synchronizing power sources, unequal load sharing between turbine generators during islanded operation, and inconsistent automatic load shedding. As a result, the plant frequently experienced power interruptions and blackouts, which significantly affected production and system reliability.

Proposed Solution:

As illustrated in Fig. 4, a load sharing and generation control system was implemented for a double-bus, ring-type 11 kV distribution network. The system employs a redundant CAN bus-based communication architecture and controls 14 circuit breakers, including the STG and grid incomers, as well as the bus-tie and bus-coupler breakers. The system integrates intelligent source controllers on each STG and the grid, enabling seamless synchronization, stable load sharing, and reliable power flow. In addition, an automatic load-shedding scheme was deployed, based on load priority, contingencies, frequency thresholds, and steam pressure levels, to safeguard critical operations during disturbances. The system has demonstrated satisfactory performance in field operation over a significant duration.

- Conclusion

The adoption of ILMS built on the IEC 61850 framework provides a modern and reliable solution for industrial power management. By leveraging logical nodes, GOOSE messaging, and MMS communication, it enables fast decision-making, seamless interoperability, and advanced generation control. With IEC 61850 enabled relays ensuring real-time response without additional wiring, ILMS enhances reliability and safeguards critical operations. Case studies from tire and paper industries demonstrate its ability to improve load sharing, optimize shedding, minimize blackouts, and maintain uninterrupted productivity. Ultimately, ILMS with IEC 61850 establishes a smarter, faster, and proven platform for managing complex industrial power system

Rohan K. Mehta is Director-Engineering at Elcon Engineers Pvt. Ltd., with over 17 years of experience in power system simulation and solutions alongside power automation solution. This article includes valuable contributions from Er. Shubham SR. Singh, Er. Arshad Ali and Er. Sahil Rana from Elcon Engineers Private Limited.

For more information website: www.elconengineers.com

Email: rmehta@elconengineers.com, pas@elconengineers.com, pms@elconengineers.com