Certainly, at our time the need for electrical earthing is increasing due to a combination of factors including a higher density of sensitive electronics, increased power demands, the proliferation of smart home technology, and the rise of new electrical systems like solar panels, EV charging stations etc..

Every modern society relies heavily on electronic devices, from computers and gaming consoles to advanced kitchen appliances. These devices are especially vulnerable to power fluctuations and surges. A robust earthing system is critical for dissipating excess electrical energy and maintaining a stable voltage, protecting delicate components from damage caused by:

- Voltage surges: Harmful spikes in voltage can be caused by various factors, including lightning strikes or power grid faults.

- Leakage currents: Faulty insulation can cause small currents to leak into the metal casing of an appliance. Without earthing, this poses a serious shock hazard.

- Electromagnetic interference: Proper earthing reduces electrical noise and interference that can disrupt the performance of sensitive equipment.

Growing complexity of electrically operated devices

The rise of smart homes, which integrate internet-connected devices, further increases the complexity of electrical systems and the necessity of proper earthing, which includes:

- Mitigating faults: A perfect earthing system is essential to prevent faults that could cause shock hazards, equipment errors, or even fire.

- Protecting data and devices: Many smart devices, from smart TVs to thermostats, contain sensitive electronics that must be protected from power surges and voltage fluctuations.

- Preventing harmonic distortion: Inadequate earthing in smart homes can cause harmonic distortion, which can lead to device errors and power quality issues.

Source: From freepik.com

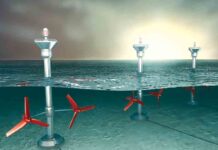

Embracing new technologies like Renewable Energys (REs) and Electric Vehicles (EVs)

The shift toward sustainable technologies has been introducing new electrical systems that need rigorous earthing standards. For example:

- Solar installations: Rooftop solar panels are vulnerable to lightning strikes and voltage surges. An effective earthing system is needed to protect the expensive inverter and panel components.

- EV charging stations: These stations require a robust earthing system to ensure user safety and protect the vehicle’s sensitive electronics during charging. Some chargers even include safety mechanisms that prevent charging if an earth connection is not detected.

Source: Photo by Trinh Trần from pexels.com

Growing infrastructure and power consumption

Developing economies and dense urban areas have a higher concentration of electrical equipment, increasing the risks associated with electrical faults.

- Rapid industrialisation: Growing manufacturing sectors and increased residential construction lead to a higher density of electrical installations, increasing the overall demand for earthing systems.

- Higher power loads: More equipment and higher power consumption amplify the potential for dangerous fault currents. Proper earthing ensures these currents are safely dissipated.

- Modernising infrastructure: Existing infrastructure, especially in older buildings, may have outdated or inadequate earthing systems that require upgrades to meet the demands of modern electronics.

Ever-increasing stress on safety and legal compliance

Along with the growing electrical risks, the regulations governing them are also toughening, which are aimed at:

- Minimising risk: Adequate earthing provides a safe path for excess current, minimising the risk of electric shocks, fires, and equipment damage.

- Meeting legal standards: Compliance with national and international electrical codes, such as those from the International Electrotechnical Commission (IEC), is a legal requirement in many regions.

Indian earthing compliance is governed by the Electricity Act, 2003, the Central Electricity Authority (Measures Relating to Safety and Electric Supply) Regulations, 2023, and the Indian Standard IS 3043, which mandates low earth resistance, corrosion-resistant materials, and regular testing to prevent electrical hazards and ensure safety. Key requirements of this include testing earthing systems annually, ensuring proper conductor sizes for different systems, providing adequate earthing electrodes, and using earth leakage protective devices to disconnect power during faults.

- Avoiding penalties and liability: Property owners and businesses can face legal and financial repercussions if an electrical incident occurs due to an improper or absent earthing system.

Glimpses of recent research findings on earthing

Recent research on electrical earthing, also known as grounding, focuses on new monitoring technologies, corrosion-resistant materials, and sophisticated soil modelling. Some of the advanced developments in this field include:

Smart monitoring systems

The Internet of Things (IoT) is being leveraged to enable real-time, remote monitoring of earthing systems. These advanced systems use integrated sensors and cloud-based platforms to continuously track the performance of buried earth electrodes. Their key features include:

- Sensor data: Voltage, current, and soil moisture sensors collect data to ensure proper conductivity and detect faults.

- Preventive maintenance: Automated alerts are triggered when readings indicate potential problems, enabling predictive and corrective maintenance.

- Fault detection: Artificial Intelligence (AI) algorithms, such as Deep Learning, interpret sensor data to provide accurate diagnostics and identify degradation.

- Reduced risks: Continuous monitoring minimises the risk of dangerous step and touch voltages resulting from poorly maintained systems.

Corrosion and electrode design

Research continues to address the corrosion of earthing electrodes, which reduces their effectiveness and lifespan. For example:

- Material comparison: Studies evaluate the performance of different materials, finding that copper has superior corrosion resistance to carbon and galvanized steel in most soil conditions.

- Electrolyte-driven corrosion: The main cause of soil corrosion is electrochemical inhomogeneity, leading to galvanic, micro-cell, and stray current corrosion.

- Advanced materials: Novel materials, such as biochar, are being tested as a backfill for earthing pits. When used in clay-sandy soil during the dry season, biochar was found to significantly reduce electrical resistance, improving grounding efficiency.

Advanced soil resistivity analysis

Since soil resistivity is a primary factor affecting earthing system performance, research focuses on developing more accurate modelling and measurement techniques.

- Modelling: Finite Element Analysis (FEA) methods are being developed to model soil resistivity in multi-layered, non-homogeneous soil structures. This provides better estimates of soil resistivity and helps optimise electrode design.

- Field measurements: The standard Wenner and Schlumberger methods for measuring soil resistivity are being continuously refined, with attention paid to mitigating challenges like inductive coupling and buried metallic interference.

India’s focus on electrical earthing

In India, electrical earthing is undergoing a significant transition from outdated regulations to a modernised, safety-focused framework. The primary shift is from the older Indian Electricity (IE) Rules, 1956, to the comprehensive Central Electricity Authority (Measures relating to Safety and Electric Supply) Regulations, 2023. This change, along with updated standards from the Bureau of Indian Standards (BIS), reflects an increased national focus on preventing electrical accidents.

New legislative framework and recent improvements

Central Electricity Authority (Measures relating to Safety and Electric Supply) Regulations, 2023: These regulations, effective since June 2023, are the current legal backbone for electrical safety and have replaced the outdated 1956 rules. They emphasise stringent, systematic measures to ensure safety and reliability for all electrical installations.

Key provisions related to earthing

- Mandatory earth continuity monitoring: For electric vehicle charging stations, the 2023 regulations mandate a system that disconnects the power supply if the earthing connection to the vehicle becomes ineffective.

- Systematic earthing for high voltage: For Extra-High Voltage (EHV) substations, generating stations, and industrial installations, system neutral earthing and protective frame earthing can be integrated into a common grid. The design must limit touch and step potential to safe values.

- Safety of personnel and training: All electricity suppliers, including generating, transmission, and distribution companies, must appoint a qualified Electrical Safety Officer. There is also a greater emphasis on training and safety awareness programs for personnel.

- Bureau of Indian Standards (BIS) codes: The following standards provide the technical guidelines for implementing the regulations:

- IS 3043:2018 (Code of Practice for Earthing): This standard was updated in 2018 and later aligned with the new CEA regulations and the National Electrical Code (NEC) 2023.

- Focus on design and verification: The updated codes emphasise a more scientific design of earthing systems rather than relying on outdated prescriptive methods. This includes comprehensive guidelines for verification and maintenance.

- Low resistance values: Specific maximum earth resistance values are specified for different types of installations, such as 0.5 Ω for power stations, 1 Ω for EHT stations, and 5 Ω for DTR (Distribution Transformer) structures.

By P. K. Chatterjee (PK)