Continual research to develop a clean source of energy is of primary importance nowadays as fossil fuel reserves are constantly decreasing. There are detrimental effects on environment due to their prolonged usage. Solar, wind, hydel, biomass, geothermal, tidal and nuclear energy are chiefly regarded as the possible replacements of fossil fuels. Wind energy among them is abundant, free of cost and without any environmental concerns. However, wind energy is intermittent in nature and also uncontrollable. Hence, a backup power source along with wind energy conversion system would be helpful and make the generation system more reliable. Difference in temperature at various regions gives rise to flow of wind. The kinetic energy of moving wind is converted into electricity in wind turbine coupled to generator shaft.

The mechanical power from wind is converted to either Direct Current (DC) or Alternating Current (AC) using DC generators or AC generators respectively. The DC generator has commutator and brush assembly which are prone to mechanical failures. Also, an inherent converter is required to produce the more convenient to use AC for both industrial and household usage. The AC synchronous alternator can generate at any speed corresponding to rotor speed. While this is an advantage especially at low wind speed conditions, a converter is required for fixed frequency operation. Induction Generators (IG) are mostly used in generation of electrical power from wind. Also, induction generators can be used in small hydro schemes with great effect. These generators are used for low and medium power generations. The principal advantage of the induction generator is its brushless and robust construction, low cost and that it does not need a separate DC excitation or does not require grid synchronization (in case of grid connected generation). Induction generators can be assumed as the best alternative for power generation from a wind energy conversion system especially for grid-isolated domestic applications.

For grid-isolated induction generators, the voltage build-up takes place when capacitors of suitable value are connected in across the stator windings. The capacitors provide the magnetizing current necessary for maintaining the magnetic field. These IG’s do not depend on the power system for excitation and are hence called self-excited induction generators (SEIG).

- Three-phase Self-Excited Induction Generator (SEIG) can be built using a three-phase induction machine with per-phase connected terminal capacitors across the stator terminals. Three-phase loads can be connected across the stator terminals, once the generator starts to generate.

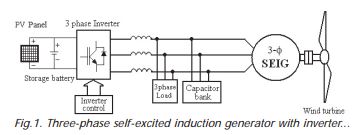

- Inverter assisted three-phase induction generator where the excitation requirement of a three-phase induction generator with change in load may be supplied from a static excitation converter like a three-phase inverter. The inverter DC bus may be alternatively connected to a photovoltaic (PV) panel as shown in Fig.1. The PV panels help in supplying real power when the generated power through IG alone is insufficient to meet the load. The PV panel can also act as a source of reactive power during varying loads and wind speeds.

- Sometimes, a switched capacitor may be connected across stator terminals for supplying the extra reactive power requirement with change in loads or wind speeds for SEIGs. This practice is avoided nowadays because this causes switching transients.

- The three-phase SEIGs are favourable units for supplying small industrial loads. Although a lot of research has been done on large scale wind energy generation, only a handful of research has been done for small scale electricity generation from wind.

- Single-phase self-excited induction generators for supplying single-phase domestic and industrial loads are also being researched. For these induction machines, two windings are commonly available in the machine stator – the main and the auxiliary windings. One winding can be used to supply the excitation requirement of the machine while the other may be used to deliver power to the load. Single-phase SEIG suffers from the problem of voltage regulation and also poses problems in determination of excitation requirements.

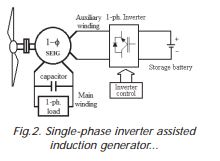

- Inverter assisted single-phase induction generator scheme aims to increase the operating range of the generator and is shown in Fig.2. However, the issue of load voltage collapse may arise in inverter assisted IGs if load current increase, as a single battery may drain out with increase in load necessitating requirement of a backup source.

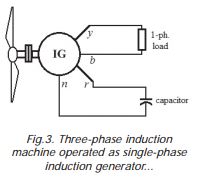

- Three-phase induction machine is a cheaper alternative to a single-phase induction machine for similar power ratings in the upper ranges of power above 0.75 kW. Also, a three-phase induction machine will generally have smaller stator frame size than single-phase induction machine, which will enable the machine to be installed in smaller space. A suitable alternative of a single-phase IGs for micro power generation is a three-phase induction machine working as a single-phase IG supplying single phase loads.

- Three-phase induction generator supplying single-phase loads can be thought as an alternative way of generating single-phase power. Such a scheme is shown in Fig.3.

The major drawback of a three-phase induction machine operating as a single-phase IG is its asymmetrical excitation or unbalanced loading arrangement. This creates unbalanced current flow in the stator and hence de-rating the generator is employed in all such schemes to limit the stator unbalanced currents.

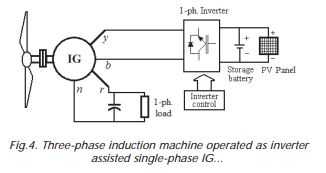

- Three-phase induction machine with PV assisted inverter excitation is beneficial scheme than conventional generator of similar ratings for single-phase, grid secluded applications. With proper control, such a scheme of generation can be made balanced. Such a scheme effectively uses an inverter at the stator terminals. This scheme is shown in Fig.4.

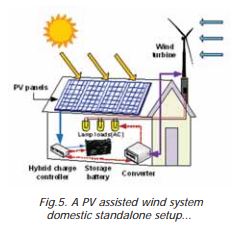

A PV assisted wind standalone system is beneficial – as it increases reliability of supply. However, the economic consideration for such a scheme (Fig.5) has to be beneficial to the end user too.

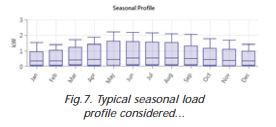

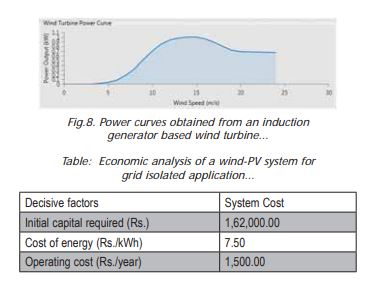

An economical analysis is carried out for a single-phase generation using a wind turbine harnessing 1kW of power. Some decisive factors are taken into consideration for overall economic analysis. These factors include initial capital required to develop a wind-solar system, cost of energy and operating cost. A simulation study is conducted for the same using a conventional wind turbine system with rectifier-inverter (converter) and a wind turbine with PV panel and storage battery for the proposed system. The simulation is done based on projection time duration of 25 years with a domestic load of 5kWh/day and 600 Watts-peak load. The simulated system is shown in Fig.6, with the seasonal domestic load profile in Fig.7. Typical power curves obtained from an induction generator based wind turbine connected to the system is shown in Fig.8. The principal requirement for the proposed system includes the wind turbine–generator set priced at Rs. 1,00,000/unit for a 1kW machine. The operation and maintenance cost is taken as 2% of the initial capital cost of the turbine. Cost of the converter system is taken at Rs. 7,000/unit for a 800VA system considered. For the proposed system, it is evident that the initial capital requirement is increased due to the use of PV panels priced at Rs. 25,000 for a 430W panel including charge controller.

12V 150Ah, lead-acid deep cycle battery is chosen which is priced at Rs. 15,000/unit which increases the initial cost of the system. The cost of energy comprises the costs for 430W PV panel, two battery units and 1kW wind turbine with inverter system for supplying the domestic load. Periodical cleaning of PV panel surface and watering of batteries are to

be considered. The payback period of the simulated system is 25 years, by the time when purchased initial cost of the scheme will diminish and hence the system can be regarded as a cost effective for long run.

The batteries can be used to:

- Provide electricity during periods when the radiation obtained from the sun is low and during the night hours.

- Also, the batteries supply the necessary reactive power with aid from the PV panels during varying loads or during low wind speed operation.

- The system reliability is increased with PV panels and battery during fluctuating loads or low wind speeds whereas conventional IG systems are highly dependent on terminal capacitors only.

- However, there are some challenges associated with installing such a system.

- The engineering challenges presented by the structures, controls, electrical conversion and associated electronics are formidable.

- There is a need for satisfactory research cooperation between the private and public sectors to actively develop and use small scale wind generation technology indigenously.

Integrating a PV system although will increase the initial cost but will be a reliable technology for a domestic grid isolated system as shown.

If you like this article or want to share your thoughts or feedback, please leave a comment below.