The notion of Industry 5.0 is progressively evolving in response to rapid technological advancements. Emerging digital technologies, most notably machine learning, artificial intelligence, industrial wearables, virtual reality, and are reshaping the dynamics of human–machine interaction.

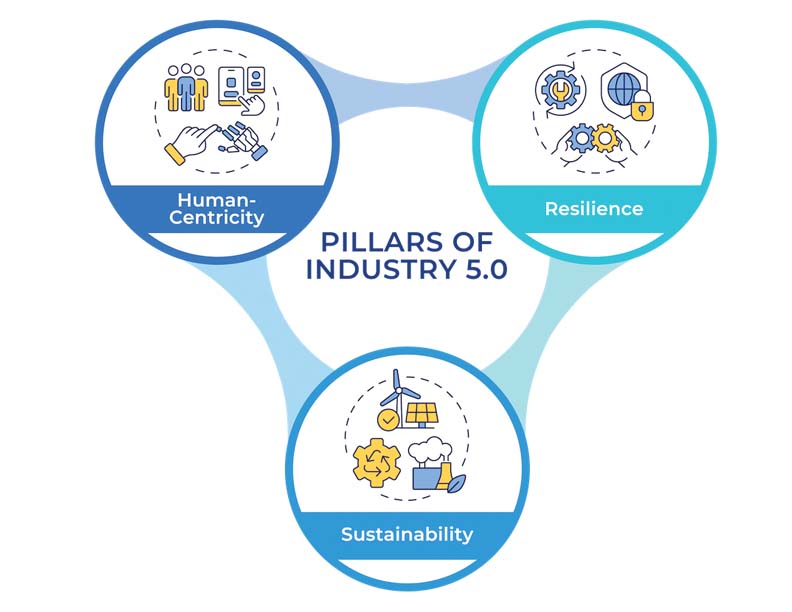

These innovations present opportunities not only to optimise operational efficiency but also to foster more sustainable, inclusive, and human-centric industrial ecosystems. The approach of Industry 5.0 envisions a future in which human creativity and advanced digital technologies collaborate in a synergistic manner, fostering unprecedented levels of customisation, sustainability, and resilience.

By placing human needs and values at the core, this paradigm shift emphasises the development and adoption of emerging technologies in accordance with robust ethical standards. Such an orientation not only safeguards societal well-being but also ensures that innovation contributes to more inclusive, responsible, and future-ready industrial ecosystems.

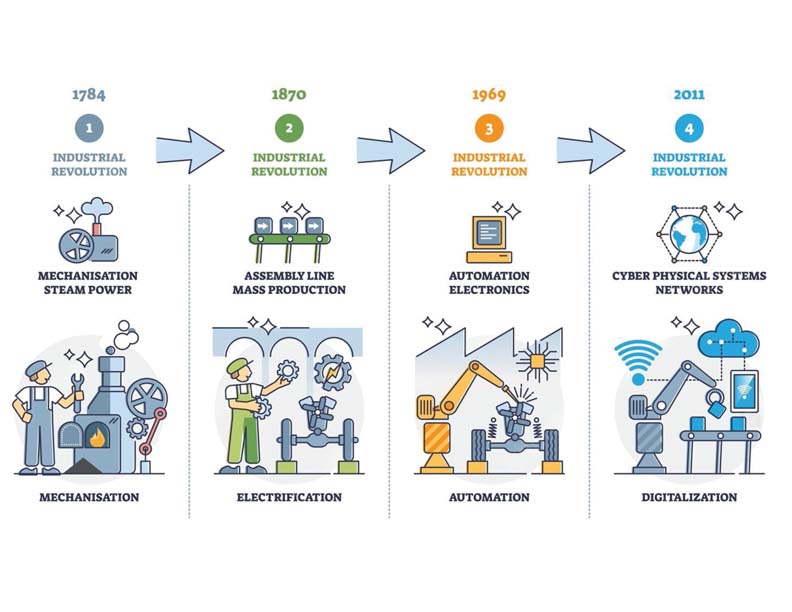

History of industrial revolution

The progression from steam-powered machinery in the era of Industry 1.0 to the strategies for integrating new technologies into IT transformation in Industry 4.0 illustrates a remarkable trajectory of industrial and socio-economic transformation. Each numbered stage reflects a distinct period of technological advancement, characterised by defining innovations: the steam engine in Industry 1.0, electrically driven machines in Industry 2.0, use of control systems to manage machines in Industry 3.0, and digital revolution in Industry 4.0.

Collectively, these milestones highlight not only the evolution of production systems but also their profound influence on societal structures and economic development. Industry 5.0 integrates digitalisation with a broader agenda of sustainability, directing its application toward pressing environmental, energy, and societal issues.

Drivers of Industry 5.0

While Industry 4.0 technologies primarily advanced efficiency through automation, they have also been criticised for their limitations. The paradigm, as currently conceived, has proven inadequate in the context of interrelated crises of climate change and biodiversity loss, and growing social tensions. Instead, it remains structurally aligned with the optimisation of business models and economic logics often regarded as root causes of today’s environmental and societal challenges. Consequently, although Industry 4.0 contributed to greater productivity and efficiency, it fell short of embedding broader values of sustainability, resilience, and inclusivity into industrial systems.

In response, the emerging paradigm of Industry 5.0 seeks to create manufacturing and production environments that are not only efficient but also sustainable, resilient to external shocks, and agile in adapting to evolving business and societal challenges. By placing human needs and values at the forefront, Industry 5.0 envisions a future in which technological innovation is guided by ethical standards, environmental responsibility, and social well-being.

The COVID-19 pandemic severely disrupted global manufacturing, with emerging economies such as India experiencing significant setbacks. Large segments of the manufacturing sector were forced to halt production, while many enterprises faced challenges to their continued survival in the wake of prolonged uncertainty.

These disruptions exposed the vulnerabilities of global supply chains and underscored the need for more resilient, adaptive, and human-centric systems. In this context, Industry 5.0 offers pathways to overcome supply chain fragilities by fostering closer collaboration between humans and advanced technologies, thereby enhancing agility, flexibility, and sustainability in post-pandemic recovery.

Industry 5.0 in India

The manufacturing sector in India stands at the threshold of a significant transformation with the advent of Industry 5.0 technologies. The fast-evolving landscape of technology combined with the changing dynamics of the labour market necessitates the acquisition of new skill sets. To remain competitive and adaptive in this fast-evolving environment, individuals must continuously update their competencies. Consequently, there is a pressing need for initiatives that promote lifelong learning and continuous skill development, ensuring that the workforce is adequately prepared for the future of work within an Industry 5.0 framework.

India’s education sector is currently undergoing a profound transformation, evidenced by initiatives such as the revised National Education Policy (NEP), strengthened global industry–academia linkages, and the growing integration of new-age technologies.

These changes have been further accelerated by the COVID-19 pandemic and the rapid expansion of educational technology (EdTech), which have collectively reshaped teaching and learning practices. In this evolving landscape, there is an increasing demand for personalised, flexible, and outcome-oriented approaches to education, thereby paving the way for the emergence of Education 5.0.

Conceptualised as the convergence of advanced technologies with human-centric pedagogies, Education 5.0 emphasises individual empowerment, innovation, flexibility, and inclusivity. By equipping learners with the ability to navigate and adapt to shifting technological and socio-economic trends, Education 5.0 represents a forward-looking framework for preparing students to thrive in an increasingly complex and dynamic world.

Industry partnerships play a pivotal role in equipping students with market-relevant skills, thereby enhancing their preparedness to address real-world challenges. In parallel, higher education in India has witnessed a substantial rise in research funding, particularly through initiatives such as the Impactful Policy Research in Social Science (IMPRESS) and the Scheme for Transdisciplinary Research for India’s Developing Economy (STRIDE).

Collectively, these schemes have allocated more than INR 1,000 crore, reflecting a strong policy emphasis on fostering innovation, interdisciplinary research, and knowledge creation within the academic ecosystem.

Initiatives at educational institutions

- International Humanoid Robotics Foundation (IHRF)

- STEM mentorship programme for schoolgirls

- Implementation of Fully Flexible Credit System (FFCS)

- Simulation-based learning

Centre for Human-Centric AI to ensure that AI adoption is guided by ethical standards, regulatory frameworks, and social responsibility, large language models, and collaboration between academia, government, and industry for Industry 5.0-aligned solutions.

Technology Innovation Hubs (TIH) specialising in Artificial Intelligence and Machine Learning have been set up.

Initiatives by GoI towards Industry 5.0

- The National Policy on Industry 4.0

- Mission on Internet of Things (IoT)

- National Mission on Quantum Computing and Technology

- Digital India Mission

- National Mission on Artificial Intelligence

- National Mission on Robotics

Sustainability with Industry 5.0

Circular Economy principles are increasingly being adopted as a means to reduce waste and emissions while promoting resource efficiency. Manufacturers are now redesigning products so they can be reused, using more recycled materials, and making products last longer. These efforts support global sustainability goals while also are reducing dependence on raw resources. In Europe, such practices have already increased the use of recycled materials to 11.8%, strengthening supply chains and supporting the vision of Industry 5.0.

At the same time, industries are adopting advanced systems to monitor emissions more accurately. Continuous Emission Monitoring Systems (CEMS), valued at USD 4.3 billion globally, are becoming an essential part of the shift toward greener and more responsible industrial operations. Looking ahead, these initiatives are expected to expand further, with digitalisation and responsible AI playing a central role in driving sustainable growth and shaping the future of industrial transformation.

Complementing these developments, Artificial Intelligence (AI) optimisation tools are driving efficiency through data-driven operational adjustments. For example, an automotive plant achieved a 15% reduction in energy consumption by using AI-enabled real-time energy monitoring and control.

In addition, predictive maintenance and intelligent scheduling of production helped minimise downtime and move workloads to off-peak hours, leading to a further 12% reduction in energy costs. Alongside digital solutions, technological innovations such as waste-heat recovery systems have cut fuel consumption by nearly 20%.

Similarly, the adoption of Combined Heat-and-Power (CHP) installations has improved overall facility energy efficiency, raising it from about 50% to nearly 75%. Together, these advancements highlight how Industry 5.0 technologies and sustainable practices can work hand in hand to reduce environmental impact while strengthening industrial competitiveness.

Risks and opportunities in Industry 5.0

Although Industries 4.0 and 5.0 are already in operation, they have introduced several operational challenges for digital supply networks and interconnected smart industries. A key concern lies in the industrial value chain’s limited capacity to promptly mitigate the consequences of cyber-attacks, which could have severe implications. The lack of adequate preparedness for such risks highlights significant vulnerabilities that must be addressed to ensure the resilience and security of next-generation industrial ecosystems.

As Industry 4.0 moves ahead to Industry 5.0, mitigating cyber risks requires strong, persistent, and fully integrated cybersecurity strategies. The widespread adoption of IoT has expanded the attack surface, offering greater opportunities for cyber threats. To enhance infrastructure security, Industry 5.0 increasingly employs blockchain-based access control and AI-driven Intrusion Detection Systems (IDS), representing a significant advancement over the approaches used in Industry 4.0.

Nevertheless, Small and Medium-Sized Enterprises (SMEs) continue to face vulnerabilities due to fragile supply chain connections, limited cybersecurity awareness, and inconsistent risk assessment practices. Critical sectors such as healthcare face additional challenges related to data privacy and IoT integration.

Furthermore, organisational barriers – such as employee resistance, high implementation costs, and shortages of skilled professionals – continue to hinder effective cybersecurity adoption.

The Fifth Industrial Revolution is expected to be driven by Collaborative Robots (cobots), advanced robotics, and artificial intelligence, which will play key roles in transforming industrial systems. These technologies will not only improve efficiency and productivity but also support sustainable practices and create a more human-centered approach to manufacturing and industrial operations.

Yet, despite these technological capabilities, human intervention remains essential for modification, personalisation, and decision-making. A major challenge lies in sourcing workers with the specialised skills required to operate within these advanced environments, which also necessitates fair compensation and continuous training.

Effective management practices are therefore critical to preparing a workforce capable of thriving in smart manufacturing ecosystems. At the same time, several technical challenges persist, including the high costs and complexity of training and testing, management of large state spaces, and issues related to data storage and collection.

Way forward – Walk the talk

Positioning industry as a pillar of sustainability, ecological regeneration, and social inclusion – rather than as a source of threat – places fundamentally new demands on governments, public policy, and state–industry relations. First, it necessitates the development of innovative policies, policy instruments, and partnerships, along with revised objectives for industrial policy. Second, it calls for a portfolio-based approach to research and innovation projects, underpinned by a mandate to take informed risks. Third, agility is required, both in terms of resource fluidity – the capacity to rapidly allocate and reallocate financial and other resources – and in the ability to respond effectively to shifting circumstances. Finally, governance must improve its capacity to link policy processes, policy domains, and governance levels in a more coherent and user-friendly manner, where ‘users’ encompass industries, citizens, and wider stakeholders. In essence, the advancement of

Industry 5.0 requires a parallel evolution toward Government 5.0.

Recent European priorities, such as energy efficiency and responsible water use in industrial operations, highlight the need for reliable Key Performance Indicators (KPIs). High-level experts have stressed that realising the transformative potential of Industry 5.0 will require substantial public and private investment, with principles of Industry 5.0 embedded into funding conditionalities.

They further emphasised the necessity of integrating these principles across entire value chains, supported by key enablers such as adopting the learning-organisation model of continuous improvement, fostering workforce empowerment, ensuring data accessibility, and advancing upskilling and training initiatives to prepare the workforce for the demands of Industry 5.0.

Tata Consulting Engineers gearing up for Industry 5.0

Tata Consulting Engineers (TCE) leverages its strong engineering foundation and digital innovations to deliver end-to-end solutions worldwide. Over the past six decades, TCE has executed complex projects across sectors, including power plants, smart cities, bridges, and iconic landmarks. such as the world’s tallest statue.

Partnering closely with clients, TCE supports the full project lifecycle – from concept and design to procurement, construction, and commissioning – ensuring efficiency and lasting value. We support owners and operators in digitising engineering and plant information accessible to all stakeholders.

Leveraging the Industry 4.0 solution stack, we facilitate the digital transformation of plants, enabling optimal asset performance and streamlined operational processes. Other services include 3D engineering, 4D and 5D simulation, Building Information Management, Asset digitalisation and Asset Information Management, Product Engineering and Turnkey Machine Development.

Conclusion

Industry 5.0 places strong emphasis on advancing the United Nations Sustainable Development Goals (SDGs), with particular focus on health and well-being (SDG 3), decent work and economic growth (SDG 8), industry, innovation, and infrastructure (SDG 9), and sustainable cities and communities (SDG 11). These objectives are further supported by the broader framework of Society 5.0 and the shift from Industry 4.0 to Industry 5.0. Breakthrough technologies play a critical role in enabling innovative business models, strengthening disaster management, and advancing healthcare with digital solutions. They also contribute, at least partially, to the achievement of other SDGs, including no poverty (SDG 1), zero hunger (SDG 2), quality education (SDG 4), clean water and sanitation (SDG 6), affordable and clean energy (SDG 7), and responsible consumption and production (SDG 12).

Interactions among these goals indirectly influence the pursuit of the remaining SDGs. While Society 5.0 underscores responsible utilisation, Industry 5.0 simultaneously aims to foster increased production, adaptability, and efficiency within industrial ecosystems.

Sandhya Mukherjee, a graduate in Electronics and Power from Visvesvaraya National Institute of Technology, Nagpur, has been working in power sector with experience of design engineering, consulting, quality management and operations of thermal power stations. Presently she is working in Technology Vertical of Tata Consulting Engineers Ltd., in the role of Assistant General Manager.