Electrical transformer is one of the important equipment in the process of transmission and distribution of electricity. Transformer is the costliest equipment of power system and its proper functioning is vital to system operations. Fault is significant in all electrical devices. A fault in transformer can cause failure and result in significant property damage and serious interruption to a business. A simple fault in distribution side can cause black-out of power in the whole area. Generally, transformer requires very less maintenance as compared to the other electrical equipment, but to track the cause of failure and the origin of a defect is not simple. Causes of failures are not just from a single factor. But these are generally combination of many factors. These factors include imperfection in design and environment.

One of the main causes of failure of a transformer is the insulation failure. The purpose of the insulation is to prevent the flow of electric current between points of different potential in an electrical system. Failure of insulation is one of the most common failures in an electrical equipment. The commonly used insulations in a transformer are insulating fluids, conductor insulation and solid insulator. Failure of any of these insulating medium results in catastrophic damage to transformer. The major fault and its percentage occurring in power transformer are indicated in figure 1.

Failure and Causes

The cause of failures is classified into a) electrical b) mechanical and c) thermal and these failures can be further classified into external or internal components.

Bushing

Bushes are insulating devices that insulate a high voltage electrical conductor to pass through an earth conductor. In transformer, it provides a current path through the tank wall. Inside the transformer paper, insulators are used which are surrounded by oil that provides further insulation. Bushings sometimes fail due to partial discharge. This is sometimes due to the slow and progressive degradation of the insulation over many years of energised service. However, it may also be a rapid degeneration which destroys a good bushing in few hours. Seal breaking of bushes happen due to ingress of water, aging or excessive dielectric losses. Due to this fault, core failure of the transformer occurs. Non-replacement of oil over long time or its deficiency due to leakage causes internal over-flashing. Percentage of bushing failure is indicated in figure 2.

Winding Failure

The causes of breaking of the windings or the burn-out will cause breakdown of transformer. There are different causes of breakdown of winding which are listed below.

- Dielectric faults occur in the winding due to turn-to-turn insulation breakdown. These are the insulation between the turns of the winding. Insulation breakdown commonly occurs due to high current and voltage which are high above the rated values. The breakdown of the insulation results in the flashover of the winding turns and cause a short circuit.

- The windings are usually of copper. Due to the copper line resistance, thermal losses occur. These thermal losses make hotspots in the winding due to poor or lack of maintenance. This over time causes wear and tear and the decrease of the physical strength up to the point of breaking of the winding. Figure 3 indicates the transformer burnout.

- Mechanical faults are the distortion, loosening or displacement of the windings. This results in the deterioration in the performance of the transformer and the tearing of the turn-to-turn ratio. The main reasons that cause this fault are the improper repair, poor maintenance, corrosion, manufacturing deficiencies, vibration and mechanical movement within the transformer.

- Deterioration of oil: Deterioration of oil may occur due to the result of prolonged overloading of the transformer. Excessive oil temperature produces the formation of sludge, water, and acids. Moisture entering the oil as a result of the breathing action greatly reduces its dielectric strength so that breakdown from coils or terminal leads to tank or core structure may take place. Narrow oil ducts are a serious menace to the operational life of a transformer.

Petroleum based mineral oils are the generally used fluids for electrical insulation and heat transfer. But they are non-biodegradable. Vegetable oils obtained from seeds, flowers and vegetables are biodegradable, non -toxic, environment-friendly.

The breakdown strength of both oils without moisture and oils which contain moisture at a gap distance of 2.5mm are shown in figure 4.

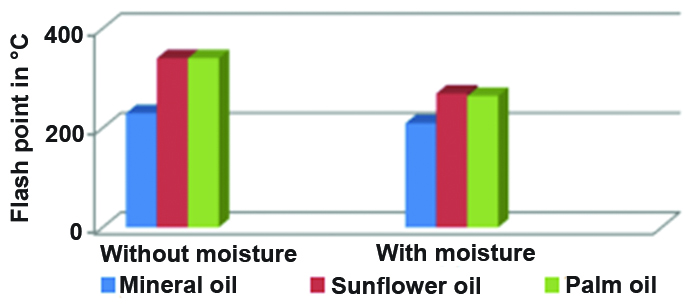

The viscosity, flashpoint and also fire point of different liquids is as shown in figure 5, figure 6 & figure 7.

Liquid dielectrics used are the most expensive components in power systems like transformers and circuit breakers. It is proved that the breakdown voltages of oils increase as the gap distance between the electrodes increases. It is also proved that the oils without moisture are better insulators than those of oils with moisture. The flash point and fire point of oils without moisture are greater when compared to the oils with moisture. Hence, oils without moisture are good.

Maintenance

For a safe and reliable operation of transformers, preventive maintenance is must. The maintenance detects problems at an early stage and can prevent further deterioration. Preventive maintenance includes oil sampling and analysis (oil quality, moist level, etc.) and electrical measurements (insulation resistance, winding resistance, etc.).

The protection system is to protect the transformer from faults by first detecting the fault and then resolving it as fast as possible. If it cannot fix the fault, it isolates it so that it may not damage the transformer. Protection systems include the Buchholz protection, pressure relief valve circuitry, surge protection and sudden pressure relays. The Buchholz is one of the main protection systems that detects failure in insulation of transformer as it is sensitive to dielectric faults.

The Dissolved Gas Analysis (DGA), moisture analysis and other oil tests, and partial discharge are of the most important tests that are performed on transformer. Dissolved gas analysis of transformers provides an insight into thermal and electrical stresses sustained by oil-immersed power transformers. In addition, DGA is a sensitive and reliable technique for detecting incipient fault conditions in oil immersed transformers. DGA can help prevent further damage since test can detect incipient transformer faults. Partial Discharge (PD) can be measured offline using a high voltage power source, or online as the transformer is energised—under load or no-load.

As technology has advanced, online monitoring of power transformer has been introduced. A technique called Electrical Signature Analysis (ESA) had received attention by the industries for the increase in demand of predictive technology. On-line condition monitoring reduces cost related to the operation and maintenance of installed equipment and has mentioned the need of change in time-based maintenance program to condition based diagnostic procedure and online monitoring approaches. Online monitoring to optimise the operational management is the key factor for future profitable generation, transmission and distribution within the power system.

Recent Technology for Fault Analysis

In the recent years, several researchers and transformer experts have been able to achieve significant breakthrough in developing ways and means of assessing condition of the in-service power and distribution transformers that have proved a boon for detecting incipient faults in them. As a result, catastrophic failures can be easily detected and remedial actions can be taken timely to save both human life and other capital losses in addition to preventing electric supply failures and economic losses to state electricity boards and utilities. Some of the recently developed techniques are On line Chromatography, Oil test by UV-VIS Spectroscopy, SFRA Diagnostics, Furan Analyses, Dielectric Dissipation Factor (DDF) or Tan Delta (tan d), Water in oil Analyzer, Online Transformer Temperature Monitor, Routine Inspection Monitor & Indicator device using µP, Thin film Capacitor Sensor and Use of HTS Transformers.

The basic concept behind all above methods is the idea that calls for either continuous or periodic monitoring of all key performance affecting parameters of the transformer. Any departure from its normal value indicates a fault condition which needs the utmost attention to circumvent faults of all sorts and help prevent catastrophic failures.

Dear Sir / Madam

Defects had been found concerning the operation of the 33/3.3kV oil transformer. A phase to earth low insulation reading (3 Mohm) was recorded in 3.3 kV side during the maintenance work. The Transformer oil was checked and is currently in good condition according to the results revealed in the Dielectric and Dissolved gas test.

I would be grateful if any recommendations are suggested for my further follow-up actions.

Thank you.

Helⅼo mates, its enormous piecе ⲟf writing concerning tutoringand fully defineԀ,

кееp it up all the time.