Moving towards achieving most efficient use of energy, many programs have been brought out by Govt. of India to monitor and manage energy use in the industries like ECBC, star label, PAT, SME, SDA, DSM etc. introduced by Bureau of Energy Efficiency (BEE)-Govt. of India-Ministry of power. As per the norms of energy efficiency many industries carry out energy audit in their firms to find out energy wastage and scope of improvement. For a newly installed system, audit of energy will not contribute much for energy conservation as everything was already taken care by the system design. Over a period of time addition or deletion of sub system to the existing system will change the overall characteristics. This will lead to change in the energy consumption profile which is difficult to trach without a proper study on the system as a whole. Hence energy audit can act as a tool to redefine the overall system profile to understand it better. Energy audit is not only a tool for energy conservation, it also helps up to an extent for early detection of faults in equipment by analyzing the power drawing pattern. To meet the raising demand of auditing of energy in industries, many energy auditing firms have also newly developed. This will make the process more economical for energy intensive industries due to increasing competition.

The same practice has been followed in building audit also. Addition of new sub systems to the existing system is very common in the case of buildings where load distribution may not have properly planned due to limitation on main system. But when it comes to hotel, hospital, business tower etc. equipment which consume large amount of energy are limited. Apart from the illumination system and electronics loads, air conditioning system and lifts are the only major load for such buildings. Scope for conservation of energy is limited for equipment where consumption is less. Because of this reason, many commercial buildings are not in the practice of conducting energy audit assuming that the practice will not do any good to them. Programs like Energy Conservation Building Code(ECBC), PAT scheme etc. has encouraged them to come forward and to join with the initiative of energy conservation and many organizations have become a part of it. But lack of well-defined auditing structure for building is a concern since the way of approach is different for different auditing firms. There is a high chance that at least few things will be missed by overlooking. Most of the organizations are relying on their own metering set up installed locally to have an idea of energy consumption profile. Over a period of time, drift in the measurement can lead to take inappropriate decision by the organization if this is not noticed. Hence verification of installed metering system should also be a part of the scope of energy auditing. Instead of only giving a report of technical analysis on the system, educating the industry based on the findings in energy audit is also an important part of energy conservation.

Methodology

The study was conducted on a ten storey commercial building in the city of Bangalore. This building spaces have been rented out for many customers. All the customers have different metering units installed and common load such as lift, air conditioning system etc. are monitored separately. Electrical energy is the primary source of energy used in the building. Electrical power from grid is the main source of energy and is tapped at 11 kV from grid and further stepped down to 433 V via two transformers of 2 MVA and 2.5 MVA and supplied to all the loads. Main incomer is metered by utility using class 0.5 energy meter. At the secondary sides of two transformers, there are two local metering installed. Class 1 meters are installed at secondary sides. There are 5 numbers of 1500 kVA, 415 V DG sets connected to the system to cater all the loads during power failure. This study did not include analysis of DG set as our main focus was not to analyze efficiencies of individual equipment but to understand the system for distribution, management and monitoring of energy consumption.

Measured energy data from the utility side as well as from the user side for the past one year and four months is analyzed to find out if any discrepancies in the measurement. Utility meter was installed at the primary side of the transformers whereas user meter was installed at the secondary side of the transformer. As a result of measurement at different locations there must be a difference between the values measured due to losses happening in between including transformer losses. Details are given in Table 1.

In 2019 minimum difference, maximum difference and average difference observed are 2.15 %, 6.3 % 4.01 % of total consumption respectively. In 2020 minimum difference, maximum difference and average difference observed are 2.64 %, 5.36 % 4.55 % of total consumption respectively. Average difference is maximum in 2020 which is 4.55 %. This high percentage difference between the measurements indicates that there is a severe fault in the procedure or in the measuring equipment. This has reiterated that the detailed study on the measurement procedure and measuring equipment is to be included in the study.

Study Carried Out

Incomer power quality

Power quality data were acquired at the secondary side of the transformer. Incomer voltage profile and frequency profile were analyzed and is given in Figure 1 and 2.

It is observed that there is an average of 5 V dip in R-B line voltage from other line voltages. This is observed at both the secondary sides of 2 MVA and 2.5 MVA transformer. Hence it can be concluded that the deviation in the voltage is from utility side. Frequency lies in the band of 49.81 Hz to 50.39 Hz. It is well within the limit. Variation in power factor for a typical day is shown in figure 3. Thanks to the APFC system, power factor is found to be more than 0.96.

Total Harmonic Distortion (THD) in the voltage is shown in figure 4. Variation in THD in each phase over a day is as follows,

R Phase : 2.43 % to 3.73 %

Y Phase : 2.32 % to 3.78 %

B Phase : 2.61 % to 4.00 %

As per the power quality standards which is adopted from IEEE standard IEEE 519-1992 permissible THD limit for voltage less than 69 kV is 5 %.

Similarly, Total Harmonic Distortion (THD) in the current is shown in figure 5. Variation in THD in each phase over a day is as follows,

R Phase : 6.92 % to 10.99 %

Y Phase : 6.90 % to 12.13 %

B Phase : 6.72 % to 11.17 %

As the current harmonics increases, losses in the system will also rise. Total harmonic distortion in the current is varied within the range of 6 % to 13 % which is due to huge number of electronic loads connected.

Transformer load and loss

Electric parameters are measured at secondary sides with main focus on energy consumption. Total energy consumption by load and its shares on different transformers over a period of 17 days is plotted in Figure 6. There was no much variation in daily power consumption over these days. It means that energy consumption profile is more or less constant for the entire building. It’s because of the nature of the load connected to the building and scheduled usage of the loads like lights, AC etc. Over these days, total consumption varied between 6240 kWh to 8340 kWh/day.

2 MVA transformer has taken 17 % to 48 % of total load over these days while 2.5 MVA transformer has taken 58 % to 83 % of the total. This load sharing varies based on the operation of connected loads on a particular transformer. Figure 5 represents loading pattern of each transformer for a typical day based on their rated capacity. From the loading pattern graph, it can be seen that 2 MVA transformer has been operating under 16 % of its capacity while 2.5 MVA has been operating under 10 % of its rated capacity.

Difference between the measurements taken on primary side and secondary sides of the transformers is considered as energy loss in the transformer, but it cannot be measured at the field with portable energy analyzers as the loss is very less in transformers. Since the distance of metering instruments from the transformer is less, loss occurring in the cable can be neglected. As the load on the transformer increases, variable losses also begin to increase. Transformer operates most efficiently when both the losses become equal. This happens nearly at 50 % loading. But considering practical constraints, transformers are usually made to operate in the range of 50 % to 60 % loading. Deviation in the measurements at primary and secondary sides of the transformers are shown in figure 06.

It is found that percentage difference between the measurements varies from 1.8 % to 2.8 % over these days. It varies based on the measurement value and duration of measurement. Hence it is hard to arrive at a particular value which accurately represents the approximate transformer loss. Considering the general measurement behaviour of the instruments, it can be concluded that the difference in the measured value lies well within the band of 1.8 % to 2.8 % for the loading criteria depicted above and can be averaged to 2.3 % (Percentage is based on the utilization and not based on the equipment rating). As the load increases above mentioned loss of 2.3 % varies as Cu loss in the transformer increases. Percentage calculation is not based on the transformer rating, but based on the energy consumption. This calculation method is adopted to find out the cause of huge difference between the metering by utility and the user.

Analysis of instrumentation for end use metering

Apart from these loss incurs in the remaining path of power is to be considered. This includes losses in cables, bus ways, switchgears etc. Various losses in distribution equipment is given in table 2.

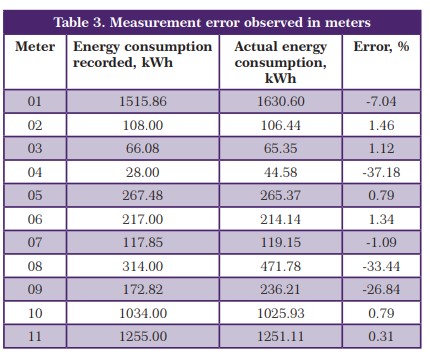

During the study it is found that the total energy consumption is not measured by a single meter but by summing up readings from 33 different energy meter installed locally at different locations of the building. Energy recorded by end user meters have been compared with measurements taken by power quality analyzers to find out the deviations in the measurements by end user meters. A duration of 24 hours is considered between initial and final measurements. 11 meters of claimed accuracy of 1 % have been considered for this exercise. Among the 11 meters measurement errors observed in 8 meters were out of maximum allowed limit as per accuracy class of respective meters and the maximum error observed was 37.18 %. Details are tabulated in Table 3.

Wrong connection of phases was found to be the cause of huge error in the energy recording instruments. This could have happened during the connections made after yearly calibration.

Conclusion

Total energy consumption in the entire building varied between 6240 kWh to 8340 kWh/day during the study period. Both the transformers are found to be operating in under loaded condition. 2 MVA transformer was operating in less than 16 % loading and 2.5 MVA transformer was operating in less than 10 % loading. Transformer loading can be optimized between 50 % to 60 % loading by de-energizing one of the transformer and connecting all the load to energized transformer by installing bus coupler could save energy. Measurement of total consumption was carried out by using 33 numbers of class 1 accuracy meters associated with CTs which are generally used for indication purposes only. This has lead to erroneous measurement of energy. In huge buildings or any other establishments, it is not practically possible to verify healthiness of each measuring and recording instruments like energy meters at different locations with limited resources of knowledge and equipment. Hence the selection of energy meters has to be carried out carefully to have a good accuracy level which is 0.5 or better in the case of energy meter. Also handling of electrical system has to be carried out by professionals and routine checkup of the system is to be carried out to identify issues with the system.

Prashob S. is an Engineering Officer, who is currently working with Central Power Research Institute (CPRI) under Energy Efficiency and Renewable Energy Division (ERED). He has experience in conducting energy audit at different establishments such as Thermal Power Stations, Hydro Power Stations, Commercial Buildings and other establishments. He is also involved in testing and research of equipment such as Photovoltaic Module, LED Luminaire, Inverter, Solar Pumps and Energy Efficient Motors. He possesses a B. Tech Degree from NIT Calicut and has an experience of more than five years in the industry.