The Customer’s Challenge

Distribution transformers are a key part of lowvoltage distribution networks. If a transformer overheats and fails, it can be devastating to the utility. A widespread outage might disrupt power to thousands of customers, and the cost to repair or replace equipment is expensive. An overheating transformer might be evidence of an improper machinery condition, progressive deterioration of the electrical isolation or machinery elements, or bad operating parameters, such as current, voltage, and temperature. With so many possible sources of the problem, it can be difficult to pinpoint the exact cause.

A Solution

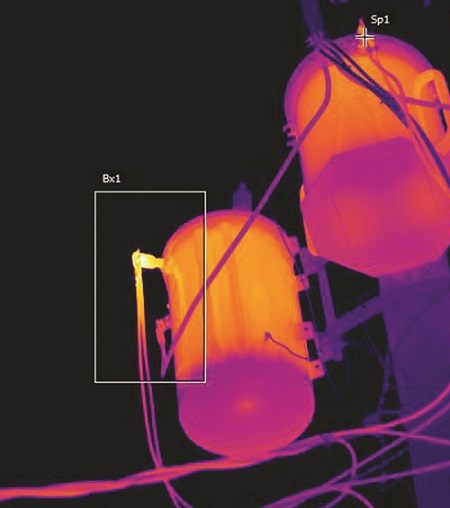

Temperature is a key element in ensuring the working status of distribution transformers. Regular temperature monitoring using advanced diagnostic thermal imaging cameras can help you catch impending failures before they occur. By using FLIR handheld thermal cameras, you can easily inspect and monitor the temperature distribution on the outside surface of each transformer. It will show you what the naked eye can’t see – hot spots that indicate overheating parts – so you know where to investigate further. The high performance FLIR T660 is an ideal solution to help you find hidden signs of electrical resistance and mechanical wear, so you can begin repairs immediately. The FLIR T660 features options with a 24-degree or 45-degree lens, which will give you a larger field of view when you have limited space in front of your transformers. This thermal camera can measure temperatures up to 2,000-degree C (3,632-degree F), and it provides 640 x 480 thermal resolution for superior image quality and clarity.

The Results

Repairing or replacing a transformer is expensive. A thermal camera pays for itself when you consider the money saved by having the ability to fix a problem before it results in a shutdown. Through regular thermal inspections, you can rapidly detect and locate overheating areas on the surface of a transformer or hot spots on electrical connections. Once you determine that something is overheating you can investigate further, such as with ultrasonic, vibration, or oil analysis. The benefits of catching hot spots early include extending the life of otherwise well-functioning equipment; prevention of equipment failures that could lead to widespread outages, reduction of costs through maintenance as opposed to replacement of damaged equipment, and improved safety by reducing the risk of fires or explosions that may result from transformer failures.

For more information about FLIR in electric power distribution, visit: www.flir.in/power-distribution